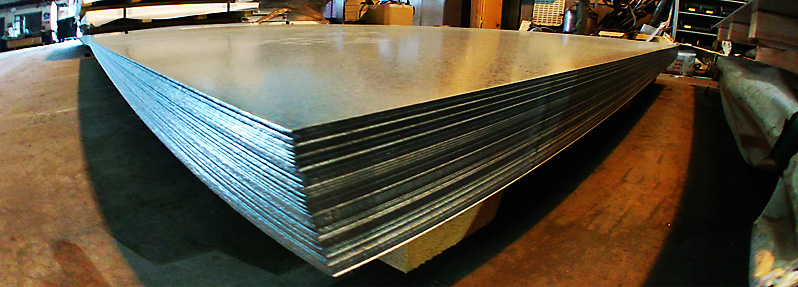

Metal formed into thin pieces is called sheet metal, and it has many applications in the building and manufacturing industries. Many kinds of metal can be formed into sheet metal, including titanium, aluminum, brass and copper. Each use for sheet metal requires a specific thickness, or gauge. A higher gauge number indicates a thinner piece of sheet metal.

The Automotive Industry

The bodies of many cars and other vehicles are constructed from sheet metal.

Airplanes

Airplanes large and small have their wings and fuselages covered in sheet metal.

A Building Material

Sheet metal can be used as a roofing material, to make flashing for roofs and to make rain gutters. Inside a building, duct work and furnaces can be made from sheet metal.

Equestrian Purposes

Sheet metal has long been used to make decorative horse tack such as breastplates.

Historical Uses

Centuries ago, sheet metal was used to make body armor for men in a cavalry.

WHY GALVANISING

Steel is a strong, versatile and inexpensive material with uses in many different industries. Galvanization is the process of applying a protective zinc coating to steel or iron, to prevent premature rust and corrosion. Hot Dip Galvanizing (HDG) is arguably the most environmentally-friendly process available to protect steel against corrosion and has many inherently sustainable features.

Several studies have demonstrated the high economic and environmental costs associated with the repeated maintenance painting of steel structures. These burdens can be significantly reduced by an initial investment in long-term protection. Lack of attention to optimal corrosion protection can leave a damaging economic legacy of repeated maintenance costs.

In social housing projects, future maintenance costs will be borne by the local authorities. In public infrastructure projects, use of galvanized steel leads to lower maintenance budgets, releasing public funds for other purposes.

Galvanising For Engineers

Engineers choose galvanising because it’s the most cost effective corrosion protection system with a long, maintenance-free lifespan. Once coated, galvanized steel is immediately ready for use. It provides a tough surface that resists immense damage and it’s environmentally sustainable.

Incorporating galvanizing at the onset of project planning ensures the highest quality coating, lowest costs, fastest turnaround times and optimum safety of galvanizing personnel.

Reduce Time and Maintenance Bills

A standard hot dip galvanized coating on fabricated steelwork, i.e. building frame, gate or appliance, give a typical life without maintenance of 50+ years in a rural environment. A paint coating could need remedial work three or four times before the galvanizing needs any attention.